It is customary for the customer to enquire about the cost involved in producing any product, especially a premium one. This is no exception to our premium range of German flour mills. It is a common retort that “Oh it’s just a motor and two pieces of stones”, customers even talk about the compact size being one of the parameters which should qualify as a parameter to reduce cost. Bigger is equal to higher cost is at times a dilemma that a customer faces while deciding about kitchen appliance. So we decided to take our keen customers to a journey which justifies what we describe as “the cost of being premium”.

The first step toward producing our Premium Mills is the work that is neither vivid nor in public domain, hence it does not get its due share of appreciation. This is represented as R & D or “Research and Development”. This is one pains taking, time consuming, at times disheartening and yet core part of process which actually prepares the ground for initial foundation for our flour mills. Once the process is successfully carried out, it culminates into ensuring that our flour mills not only meets but also exceeds the expectations of our customers. Ensuring that our Mills always deliver more than expectations it qualifies us as a Premium Manufacturer of Flour Mills. However, since this action is always behind the scenes, hence the cost, effort, heartbreaks and energy that goes into making a premium product through R & D is seldom visible or comprehended by the user or customer.

Hawos dedicates a huge amount of resources in conceptualizing, ideation, standardizing, prototyping, testing and finally launching its products. Once the Mills are in production, we stay current by researching how we can enhancing the aesthetic value, incorporate advanced technology, source and use efficient raw material all to ensure that our Flour mills continuously provide the “WOW” factor to our customers across the globe. This is invisible cost is by the core strength behind Hawos flour Mills, that provide appealing designs and ensure that they are aligned with your requirements and fulfill your needs successfully every time.

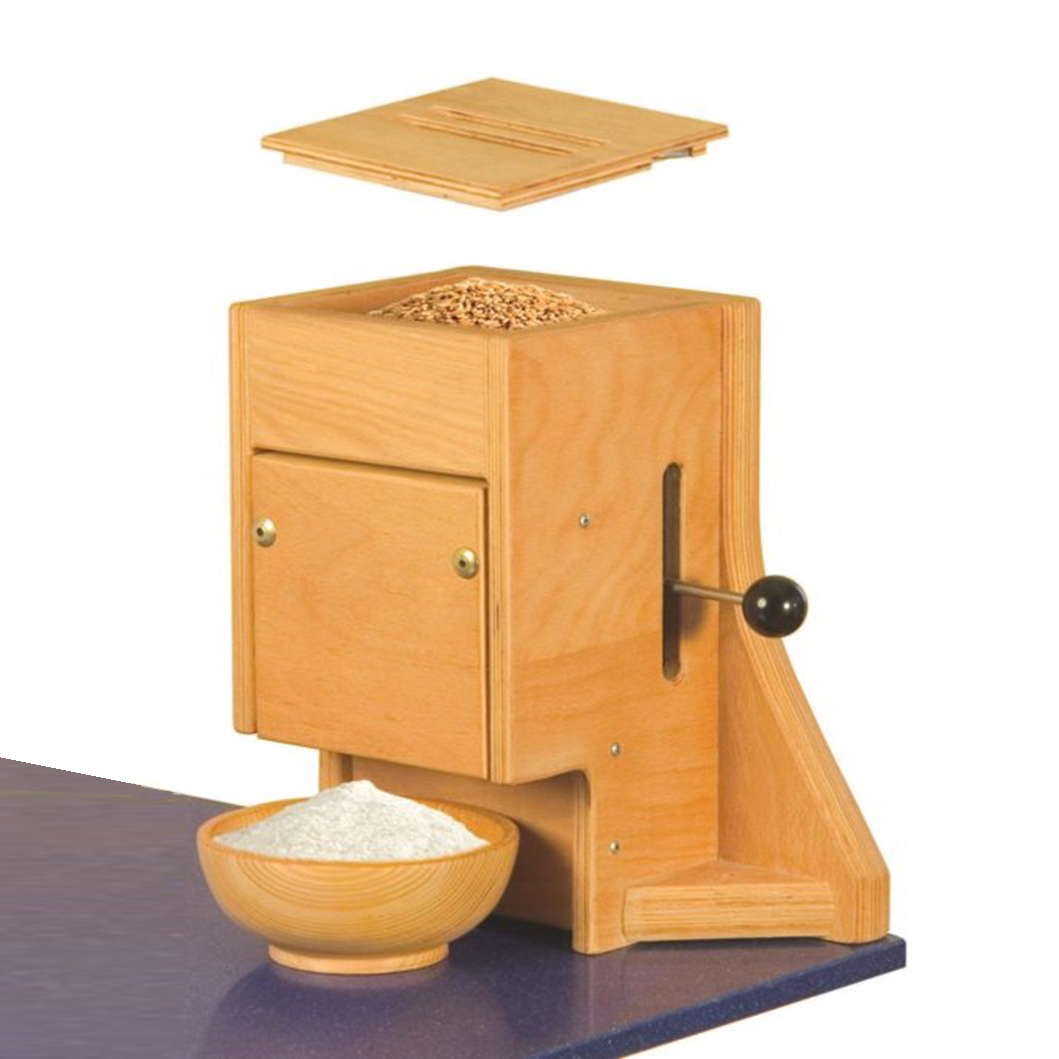

Now that you are in comprehension of the back ground process of how this wonder machine comes in existence let’s have a look at the incomparable features of this machine which will certainly more than justify its cost effectiveness. To make these domestic flour mills aesthetically appealing and deliver on quality the outer casing is made of the beach or birch wood, in either ply and solid variants depending on its model. Its smooth curves ensure that they remain the center of attraction and utility in your kitchen. Both of these woods come from PEFC certified forest complying the standards of sustainability and nature oriented practices. Both versions have natural and vital surfaces combating the consequences of unstable temperature and humidity. Moreover, these wooden bodies are treated with linseed oil for extra protection and life.

Further, the grinding stones used in these premium MINI MILLS are made of compressed oven baked ceramic corundum composites, which will leave you in nostalgia. Hawos mills delivers the ancient technique in an ultra-modern convenience. This stone is resistant to accumulation of residuals or milling debris and deliver exceptionally consistent and efficient grinding results. Grinding with this stone does not heat up the flour, consequently preserving all the nutrients and fibers to its full potential. The Ceramic corundum stones are self-sharpening, and provide an abrasive surface that grinds the grains to the required particle size with more precision. The durability and functional life of the stone is beyond expectations. Self-sharpening feature of the stone ensures consistent grinding performance and deters the stone from jamming. These stones comes in two different diameters for its 11 variants, for ultra-compact models the diameter of the stones is 70 mm and the higher capacity models the diameter is 100 mm.

Understanding the motors mechanism is an absolute delight. Besides the stone dimensions the performance is driven by motor capacity. These ultra-high performance industrial motors come in two variants 360 watts and 600 Watts, they not only consume low electricity, are super silent but also ensure consistent outputs. Adding to fine workmanship these German flour Mills are completely protected with ETA circuit breaker switches. These high-quality thermal over-current protection switches serve as on and off switches concurrently. They trip the machine off in case of any extraneous matter accidentally enters the milling material for few seconds or in case the machines are overused and get heated.

These distinctive features of these Atta chakkis are qualifiers that make the mills worthy of a premium cost. Their high performance with least efforts, tremendous health benefits and substantial aesthetic value brighten up the place around them. So your quest for mini MILLING MACHINES to make your delicacies healthier and tastier ends with these flour Mills.

We’d would love to hear your queries and response with pleasure. Please reach out to us at www.greenfuturemill.com.

Thanks for helping us to serve health to the WORLD.

What is cost of floor Mill

Hi Sir ,

Greenfuturemill Please go through our portal for pricing of all 11 models, placing an order and other amazing and useful products: https://www.greenfuturemill.com/pro…/electric-flour-mills/ or contact us at 09810558695

Hi Sir

Greenfuturemill Please go through our portal for pricing of all 11 models, placing an order and other amazing and useful products: https://www.greenfuturemill.com/pro…/electric-flour-mills/ or contact us at 09810558695